BACKSTAGE: HOW GECO ZERO IS MADE

Today, product development offers exciting insights behind the scenes: we take you on a journey through the production of the GECO ZERO lead-free jacketed bullet.

Just imagine: delicate wire is made from hard tin with great precision to create the basis for the bullet core. At the same time, the jacket that makes our bullets robust and reliable is made from tombac. All the components are put together with the utmost care to create a bullet that impresses with its precision and penetrating power.

Tin wire & cup

Before the actual production of the bullet begins, the two main components – jacket and core – are prepared. Unlike classic single-core bullets, the GECO ZERO relies on two different tin cores, which are made of individually manufactured tin wires.

- The rear core is mass-stable and ensures the desired exit wound.

- The front core is pre-fragmented and enables a quick response in the body of the game – even at greater distances.

Quality assurance ensures the precise production of all components, meeting the high GECO standards.

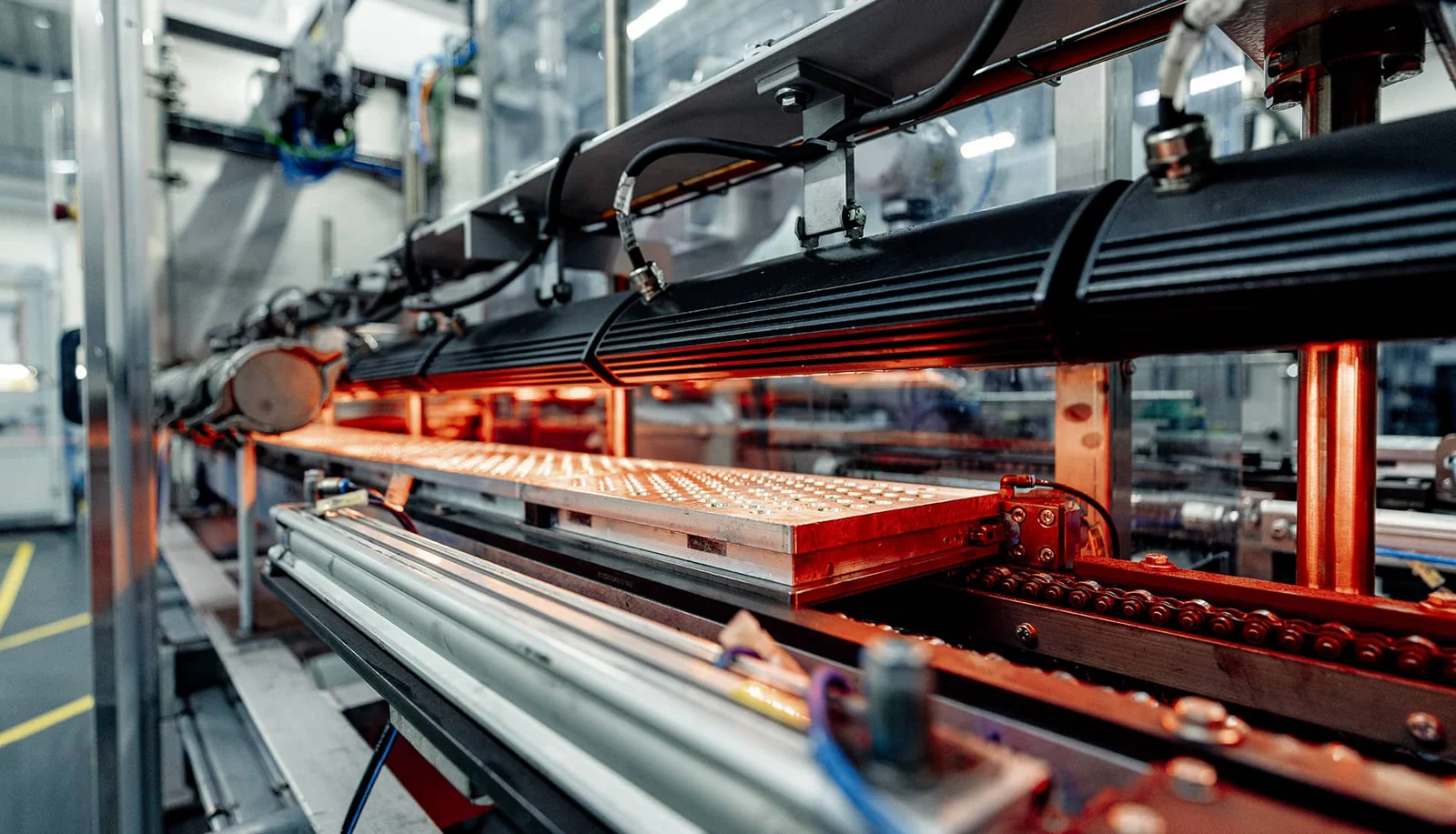

Drawing the jacket and pressing the bullet core

The GECO ZERO consists of two tin cores and a tombac-plated mild steel jacket.

- Deep-drawing the jacket

- The prefabricated bullet cup is drawn in two steps:

- In the first step, a deep-drawing process is carried out.

- In the second step, the jacket is given its final length and thickness.

Since unevenness can occur at the case mouth during deep drawing, the case is initially drawn longer than necessary. Excess material is then cut off.

- Preparation of the core

- The prefabricated cases are cleaned. At the same time, the two tin cores are cut to size, pre-pressed and cleaned on a separate machine. Only then are the components ready for assembly.

Bullet assembly

The assembly is carried out in several steps:

- Inserting the first lead core

- The rear lead core is fed in and the bullet tail is formed.

- Pressing in the second lead core

- The front lead core is pressed in in a subsequent step.

- Final shaping

- The bullet is then pressed into its final shape, given its cannelure and calibrated.

Finally, each bullet undergoes a comprehensive quality inspection. This includes a test firing to ensure that the finished batch of bullets meets the requirements for later loads.

Properties of the GECO ZERO

The special jacket design of the GECO ZERO minimises barrel fouling and enables it to be combined with other jacketed bullets made of the same material without any problems.

Thanks to its fast expansion, the GECO ZERO is particularly suitable for light to medium-weight game. The pre-fragmented front core ensures a reliable expansion even at greater distances.